Product introduction:

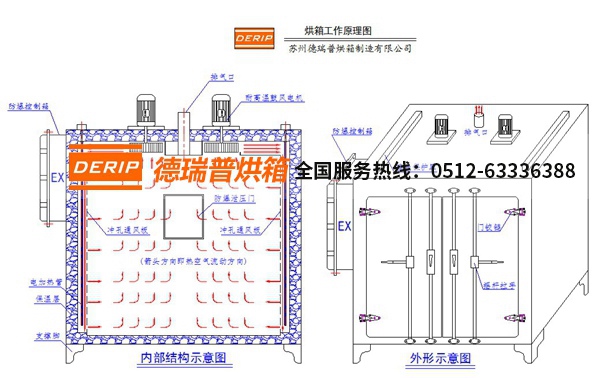

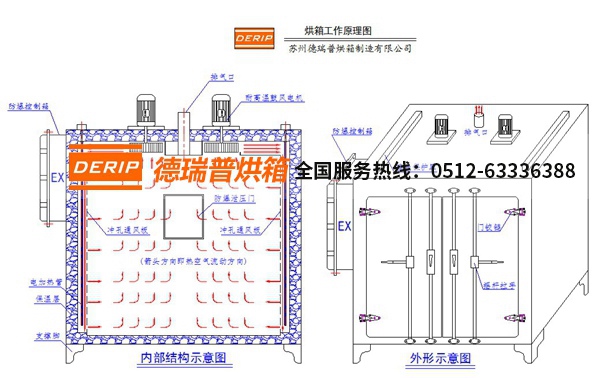

The product is widely used in the drying process of transformer manufacturing after impregnation, or for the drying treatment of paint coating surface and the drying, baking, heat treatment, disinfection and thermal insulation of general articles. The oven is equipped with a waste gas discharge interface to facilitate the discharge of waste gas. It adopts a sealed electric heater and an explosion-proof blower motor. An explosion-proof door is set behind the oven, which can effectively play an explosion-proof role and protect the safety of equipment and personnel.

Main purpose:

The transformer core and coil are soaked and dried; Casting sand mold drying and motor stator drying; Dry the product after cleaning with alcohol and other solvents.

Main parameters:

◆ studio material: stainless steel wire drawing plate (consistent with the plate of elevator)

◆ working room temperature: room temperature ~ 250 ℃ (adjustable)

◆ temperature control accuracy: plus or minus 1 ℃

◆ temperature control mode: PID digital display, intelligent temperature control, key setting, LED digital display

◆ heating equipment: sealed stainless steel heating tube

◆ air supply mode: double air duct horizontal + vertical air supply

◆ air supply mode: special blower motor for long shaft high temperature resistant oven + special multi wing wind wheel for oven

◆ timing device: 1s ~ 9999h constant temperature timing, pre baking time, automatically cut off heating and buzzer alarm when the time is up

◆ safety protection: leakage protection, fan overload protection and over temperature protection

Common specification table: (the size can be customized according to the actual needs of customers)

型 号 | 电压(V) | 功率(KW) | 工作温度范围(℃) | 控温精度(℃) | 电机功率(W) | 工作室尺寸 |

高×宽×深(mm) |

DRP-FB-1 | 380 | 9 | 室温~250 | ±1 | 370*1 | 1000×800×800 |

DRP-FB-2 | 380 | 18 | 室温~250 | ±1 | 750*1 | 1600×1000×1000 |

DRP-FB-3 | 380 | 36 | 室温~250 | ±2 | 750*4 | 2000×2000×2000 |